According to the National Retail Federation, two-thirds of consumers plan to start their holiday shopping by Thanksgiving. In 2021, 61% of respondents had already pressed start on their holiday shopping by Thanksgiving, compared to 51% a decade prior.

In this article, we’ll explore the causes and effects of these disruptions, and how companies can navigate them successfully with last-mile delivery solutions.

Holiday Supply Chain Issues for Retailers

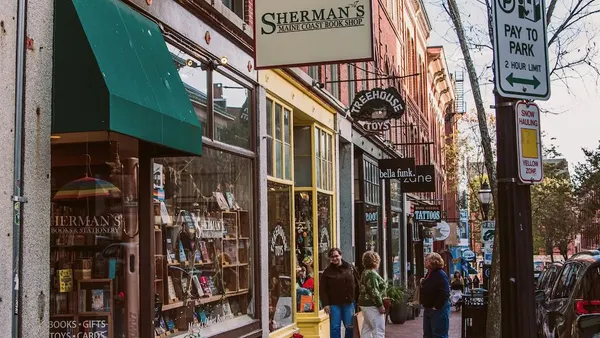

During the holiday season, customers enjoy shopping and celebrating. But for retailers, this time means careful preparation, tight stock control, and dealing with shipping problems— especially the last stages of delivery— the last mile.

Several problems can interrupt holiday shipping. The big holiday shopping rush makes these issues even trickier. Some of these problems are weather-related delays, transport congestion, and unexpected events like recent carrier strikes. Studies show that 85% of retailers worry about running out of stock during big sales events like Black Friday and Cyber Monday.

The Domino Effect on Retailers

When supply chains falter during the holiday season, the repercussions can be critical for retailers. If there are problems with getting stock during the holidays, it's a big headache for store owners. No products on the shelves or stuck in warehouses, late deliveries, or running out of items means unhappy customers. They might not buy, go to another store, or think less of your business. A study by McKinsey & Co. showed that if something is out of stock, 70% of shoppers will pick another store or brand.

Some stores don't have enough items, but others have too many. In 2022, between 30-50% of retailers had more stock than they needed. This happens because of wrong predictions, delays in shipping, and handling both in-store and online orders. Having too much stock means big discounts to sell things fast or paying more to warehouse the extra items. To make a profit during the holidays, stores must manage their stock well without spending more on their own delivery trucks. Enter last mile delivery partners.

Strategies for Mitigating Supply Chain Disruptions

- End-to-End Visibility: Monitoring your shipments from pick up to drop allows retailers to make informed decisions, optimize inventory management, and adapt quickly to disruptions. Partners and carriers that can provide real-time tracking and shareable status updates aleve the risk of empty shelves and provide peace of mind for retailers and their holiday shoppers.

- Contingency Plans: Creating contingency plans for various scenarios —- like middle- and last mile deliveries —- can prepare retailers for unexpected disruptions. These plans can include backup carriers or middle- and last-mile delivery partners for alternative transportation options. For example, if your current carrier gets delayed by holiday weather conditions or sick calls, a partner, like FRAYT, can provide professional, premium drivers and vehicles to help you recover.

- Communication and Collaboration: Choosing delivery partners that offer full transparency, as well as an open line of communication is essential. FRAYT offers a network of dedicated delivery drivers and operations professionals who are available to text or call at every stage of your shipment. Accessibility like this allows retailers to tune into their inventory’s status at a moment's notice and adapt to disruptions, no matter the stage of their shipment.

Supply chain disruptions during the holiday season are inevitable, but retailers can take proactive steps to deplete the risk. By establishing and implementing end-to-end visibility, contingency plans, and transparent partnerships retailers will secure a smoother and more prosperous holiday season for both their business and their customers.